Features and Specialties

Transmit cover opener is particularly build for AGV Project(200mm),install an automatically open cover bonding with a 300mm type load port to prevent any particle influence in an open cassette process文字內容

PLC functioning opener door going up and down.

Communicates with AGV in Semi E84

| Specifications | |

|---|---|

| 1.Ambient conditions | |

| Operation temperature | 4℃~40℃ |

| Storage/Transport temperature | 0±C~70±C |

| Relative humidity | 10%~90%(with no condensation) |

| 2.Input power supply | |

| Line connection voltage | Single~phase 100 to 230 VAC 50/60 Hz |

| Line frequency | 50/60 Hz |

| Power | 1.0kVA |

| Specifications | |

| 3.Dimensions and Net Weight | |

| Dimension(mm) | 550 X 470 X 1648 (L x W x H) |

| Net Weight (KG) | 47KG |

| 4.Precaution of Installation | |

| (1)Mounting | It has universal ball bearing at the bottom of the opener, mind the gap between opener and load port during installation. Make sure the opener and load port are 100% bonding together before foot mounting |

| (2) Power Circuit | The main power circuit is in the bottom part of the opener, If current task to move the opener please unplug the main power cable first and mind the while moving the opener. |

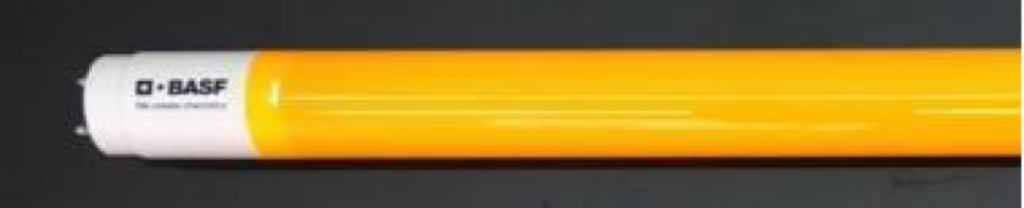

Yellow Tube for Clean Rooms

Filtrate all the <520nm blue/green light, and also maintain high efficiency, better compared to the others.

BASF yellow tube for clean room use standard white LED lights as sources, combine with organic fluorescent material into high effciency, long health yellow tube for Clean rooms.

| Product Spec | T8 LED yellow tubes for semiconductor (2 feet) | T8 LED yellow tubes for semiconductor (3.5 feet) | T8 LED yellow tubes for semiconductor (4 feet) |

|---|---|---|---|

| Rated Power (Watt) | 10W | 20W | 20W |

| Luminous Flux (Lumens) | 1000lm | 2000lm | 2000lm |

| Luminous efficiency (Lumens/Watt) | 100 lm/W | 100 lm/W | 100 lm/W |

| Size (length;diameter) | L=580mm;D=27mm | L=1050mm;D=27mm | L=1198mm;D=27mm |

| Rated Voltage | 100-277V(full voltage) | ||

| Blue/Green light filtration | <520nm Cut-off | ||

| Lifespan | >20,000 ht(L70/F50) | ||

| Cap-Base | G13(T8 LED lights fixtures) | ||

| Cover material | Optical plastic materials | ||

| Place of production | Made in Taiwan | ||

| Stroboscopic suppression | Use low strobe power | ||

| Applicable environment | Lithography Room |

24V Single-Module Battery (A)

24V Single-Module Battery (B)

| Model | SB-0240875 |

| Cell Type | LFPO(Lithium iron phosphate) |

| Nominal Capacity | 87.5Ah |

| Nominal Voltage | 26.4V |

| Charging Voltage | 29.2V |

| Standard Charging Current | 30A |

| Maximum Continuous Charging Current | 100A |

| Maximum Continuous Discharging Current | 150A |

| Discharge Cutoff Voltage | 10%SOC |

| Communication Interface | RS232 |

| Charge Temperature | 2℃~50℃ |

| Discharge Temperature | -10℃~60℃ |

| Storage/Transport Temperature | -10℃~40℃ |

| Ingress Protection Rating | IP56 |

| Certification | IEC62133,UN38.3,RoHS |

| Length | 505mm(A) |

| 405mm(B) | |

| Width | 222mm |

| Height | 238mm |

| Single-Module Battery Weight | 26±1Kg |

| Shelf Material | PC+ABS |

| Protection Type | Specification |

| UVP | Cell≦2.8V |

| OVP | 3.9V |

| OCP_CHG | 120A |

| ODP_DSH | 170A |

| OTP | ≧60℃ |

| UTP1 | ≧2℃ |

| UTP2 | ≧-10℃ |

| SC | 2000A |

24V Battery

Inherited a property and want to sell it? Cash-buyers.net offers a convenient solution and connects you with https://www.cash-buyers.net/ohio/cash-buyers-for-houses-portsmouth-oh/ who can provide a fair offer.

| Model | SB-0242100 |

| Cell Type | LFPO(Lithium iron phosphate) |

| Nominal Capacity | 210Ah |

| Nominal Voltage | 25.6V |

| Charging Voltage | 29.2V |

| Standard Charging Current | 50A |

| Maximum Continuous Charging Current | 100A |

| Maximum Continuous Discharging Current | 100A |

| Discharge Cutoff Voltage | 10%SOC |

| Communication Interface | RS232 |

| Charge Temperature | 2℃~50℃ |

| Discharge Temperature | -10℃~60℃ |

| Storage/Transport Temperature | -10℃~40℃ |

| Ingress Protection Rating | IP20 |

| Certification | IEC62133,UN38.3,RoHS |

| Length | 727mm |

| Width | 230mm |

| Height | 480mm |

| Battery Weight | 65±1Kg |

| Shelf Material | galvanized steel plate |

| Protection Type | Specification |

| UVP | Cell≦2.8V |

| OVP | 3.9V |

| OCP_CHG | 120A |

| ODP_DSH | 200A |

| OTP | ≧60℃ |

| UTP1 | ≦2℃ |

| UTP2 | ≦-10℃ |

| SC | 300A |

24V Single-Module Battery (2 battery connection)

24V Single-Module Battery (2 battery connection)

| Model | SB-0480875 |

| Cell Type | LFPO(Lithium iron phosphate) |

| Nominal Capacity | 87.5Ah |

| Nominal Voltage | 52.8V |

| Charging Voltage | 58.4V |

| Standard Charging Current | 30A |

| Maximum Continuous Charging Current | 100A |

| Maximum Continuous Discharging Current | 150A |

| Discharge Cutoff Voltage | 10%SOC |

| Communication Interface | CANBus 2.0B |

| Charge Temperature | 2℃~50℃ |

| Discharge Temperature | -10℃~60℃ |

| Storage/Transport Temperature | -10℃~40℃ |

| Ingress Protection Rating | IP56 |

| Certification | IEC62133,UN38.3,RoHS |

| Length | 505mm |

| Width | 222mm |

| Height | 238mm |

| Single-Module Battery Weight | 26±1Kg |

| Shelf Material | PC+ABS |

| Protection Type | Specification |

| UVP | Cell≦2.8V |

| OVP | 3.9V |

| OCP_CHG | 120A |

| ODP_DSH | 170A |

| OTP | ≧60℃ |

| UTP1 | ≦2℃ |

| UTP2 | ≦-10℃ |

| SC | 2000A |

48V Rack Battery

| Model | SB-0480525 |

| Cell Type | LFPO(Lithium iron phosphate) |

| Nominal Capacity | 52.5Ah |

| Nominal Voltage | 48V |

| Charging Voltage | 54V |

| Standard Charging Current | 25A |

| Maximum Continuous Charging Current | 50A |

| Maximum Continuous Discharging Current | 80A |

| Discharge Cutoff Voltage | 42V |

| Communication Interface | RS485 Modbus |

| Charge Temperature | 2℃~50℃ |

| Discharge Temperature | -10℃~60℃ |

| Storage/Transport Temperature | -10℃~40℃ |

| Ingress Protection Rating | IP20 |

| LCD Display | |

| Certification | IEC62133,UN38.3,RoHS |

| Length | 505mm |

| Width | 183mm |

| Height | 238mm |

| Single-Module Battery Weight | 24±1Kg |

| Shelf Material | PC+ABS |

| Protection Type | Specification |

| UVP | Cell≦2.8V |

| Vpack<42V | |

| OVP | 3.9V |

| OCP_CHG | 50A |

| ODP_DSH | 80A |

| OTP | ≧60℃ |

| UTP1 | ≦2℃ |

| UTP2 | ≦-10℃ |

| SC | 500A |

3U Rack Cabinet Battery

| Battery Spec. | |

|---|---|

| Model | SB-0480525-3U |

| Cell Type | LFPO(Lithium iron phosphate) |

| Nominal Capacity | 52.5Ah |

| Nominal Voltage | 48V |

| Charging Voltage | 54V |

| Standard Charging Current | 25A |

| Maximum Continuous Charging Current | 50A |

| Maximum Continuous Discharging Current | 80A |

| Discharge Cutoff Voltage | 42V |

| Communication Interface | RS485 Modbus |

| Charge Temperature | 2℃~50℃ |

| Discharge Temperature | -10℃~60℃ |

| Storage/Transport Temperature | -10℃~40℃ |

| Ingress Protection Rating | IP20 |

| LCD Display | |

| Certification | IEC62133,UN38.3,RoHS |

| Length | 440mm |

| Width | 400mm |

| Height | 131mm |

| Single-Module Battery Weight | 28±1Kg |

| Shelf Material | galvanized steel plate |

| Protection Type | Specification |

| UVP | Cell≦2.8V |

| Vpack<42V | |

| OVP | 3.9V |

| OCP_CHG | 50A |

| ODP_DSH | 80A |

| OTP | ≧60℃ |

| UTP1 | ≦2℃ |

| UTP2 | ≦-10℃ |

| SC | 500A |

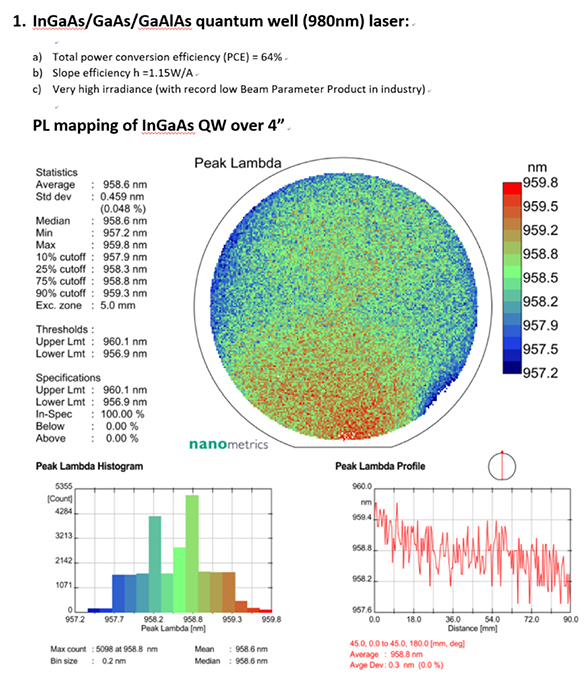

VCSEL, APD EPI Wafer

| Product items |

|---|

| InP based InGaAs APD |

| InGaAs/GaAs/AlGaAs Laser |

| InGaAsP/InP Laser |

| InGaAsSb/AlGaAsSb Laser |

| GaAs/AlGaAs HEMT |

| InAs/GaAs Hall sensor |

| InSb/GaAs Hall device |

| VCSEL |

| GaN on Si |

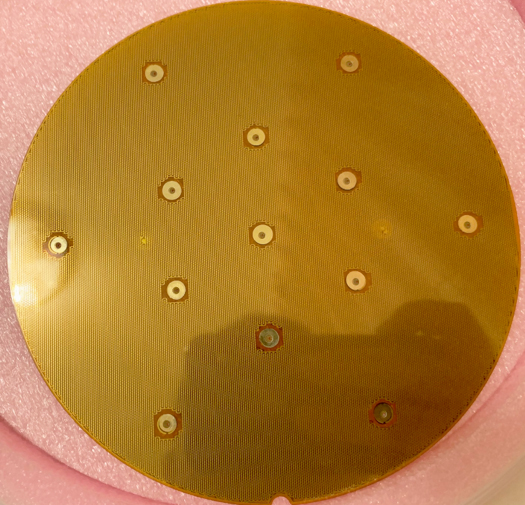

Wafer Backside Grinding BG Wheel

- Technology from SCD,Japan. Qualified by AOS,ASE(Suzhou)

- Cost advantage,Compatible with DISCO TAIKO & 800/8000 series

- Safety stock for on-time delivery

- Customized design for SiC Wafer grinding

Wafer Backside Grinding BG Wheel

厚度(um) | 252 | 251 | 250 | 250 | 251 | 250 | 251 | 250 | 249 | 250 |

| 250 | 251 | 251 | 249 | 249 | 250 | 250 | 251 | 250 | 249 | |

| 252 | 252 | 250 | 250 | 251 | 251 | 251 | 250 | 249 | 249 | |

Carrier-type E-Chuck (Supporter)

For Conductor/Semiconductor /Insulator

Carrier-type E-Chuck (Supporter)

| E-Chuck Supporter Core Technology |

|---|

| 6“/8” supporter(T:560um/TTV:10um) |

| 12“supporter(T:760um/TTV:15um) |

| Applicable for vacuum environment of temperature range (-40~200C), Wafer and supporter can perform good electrostatic adsorption. |

| Supporter can correct warpage of wafer, Avoid breakage during production |

| Supporter can be work long last by power charge one time, semi-permanent adsorption, reduce the production cost |

| Adsorption capacity: Conductor/Semiconductor: 130~180g/cm2 |

| Insulator:30~60g/cm2 |

| Customization is available for anyprocess application |

Ion beam Sputter/Ion beam Etch/ Gas Cluster Ion Beam

Application:

- Mold surface(WC)treat

- Diamond surface treat

- Substrate surface smooth

- 3D hole side wall smooth

Ion beam Sputter/Ion beam Etch/ Gas Cluster Ion Beam

| Materials for treatment 《Whole area treatment or Specific area treatment》 |

|---|

| For semiconductor: Si, Ta, Ti, Ag, Pt, Cu, Au, W, Zr, Cr, AlN, Mo,SOI film,GaAs, SiC |

| Quartz Glass (Lens) |

| Magnetic material |

| Specific fragile material:BBO LBO, LT, LN, LiTaO3, LaF3,MgF2, GaSb |